Brand Name: COORIG

Model Number: ADL-1-1250

Place of Origin: Tianjin, China (Mainland)

Main Features:

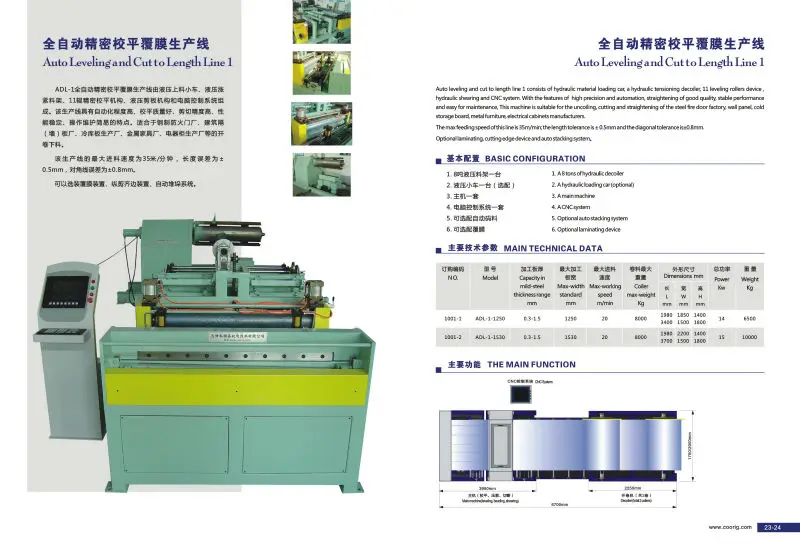

Auto leveling and cut to length line 1 consists of a hydraulic material loading dolly, a hydraulic tensioning material frame, 11 leveling rollers device, hydraulic shearing and CNC system. with the features of high precision and automation, straightening of good quality, stable performance and easy for maintenance, this line is usually used by the steel fire door and window factory, metal furniture factory and electrical cabinet factory for sheet metal uncoiling, cutting and straightening.

The CNC system with a closed-loop and servo-system guarantees processing precision.

Optional hydraulic material rack and auto-stacking system.

This line can cut metal sheets into various sizes.

The max feeding speed of this line is 20m/min, the length tolerance is ±0.5mm and diagonal tolerance is 0.8mm.

Laminator, cutting edge device, auto collection for waste material and pneumatic stacking can be added according to customer requirements.

Products Features:

A high degree of automation, leveling of good quality;

High cutting precision, stable performance, easy operation and maintenance

Suitable for steel fire door factory, metal furniture factory, electrical cabinets production factory decoiling blanking

Basic Equipment:

A hydraulic material frame with ,ax-loading of 8 tons

A hydraulic loading dolly

A main machine

A CNC system

Opitional auto-stacking and laminating device

Tianjin COORIG Technology Co., Ltd. was established in 2004 which is a professionalmanufacturer for HVACduct processing equipments and sheet metal forming equipments; our company has passed the ISO9000 certification and BV certification, develop a stable, efficient and automated product is our responsibility.

We have a after-sale service, Warranty 12 months

Our Logo: